If the objective of the analysis is to determine the probability of failure of the product, regardless of the mode responsible for the failure, we would analyze the data with all data entries classified as failures complete data. Personal tools Log in. Flexible results, plots and automated reports to quickly provide the results, plots and reports you need to support decisions based on analysis results. For example, under certain circumstances, and depending on the question one wishes to answer, a specimen that has failed might be classified as a suspension for analysis purposes. In other words, it could have failed any time between 0 and hours.

| Uploader: | Maukus |

| Date Added: | 21 March 2014 |

| File Size: | 43.26 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 59368 |

| Price: | Free* [*Free Regsitration Required] |

The acceleration factor for a temperature of K is approximately 8. This can be achieved with fractional failures.

Accelerated Life Testing and ALTA

Stress plots are the Arrhenius and the inverse power law plots. Flexible results, plots and automated reports to quickly provide the results, plots and reports you need to support decisions based on analysis results.

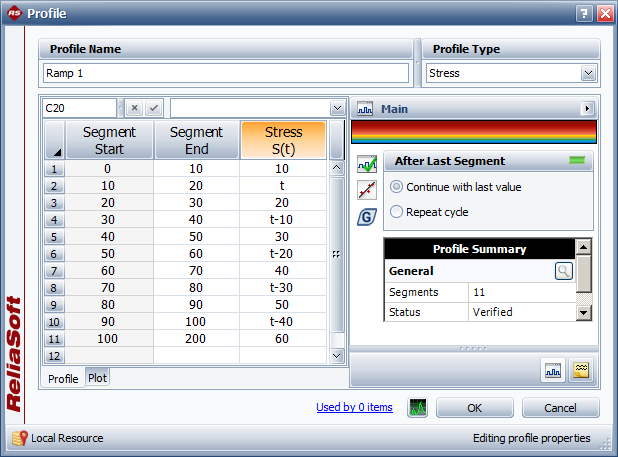

Additionally, ALTA includes Stress Profile Plots for each cumulative damage analysis that shows both the profile and the failures that occurred in each segment.

You can estimate the parameters of the entire model, including both the life-stress relationship and the use-level life distribution. For example, if the inspection altx is too long, all relasoft units in the test may fail within that interval, and thus no failure distribution could be obtained.

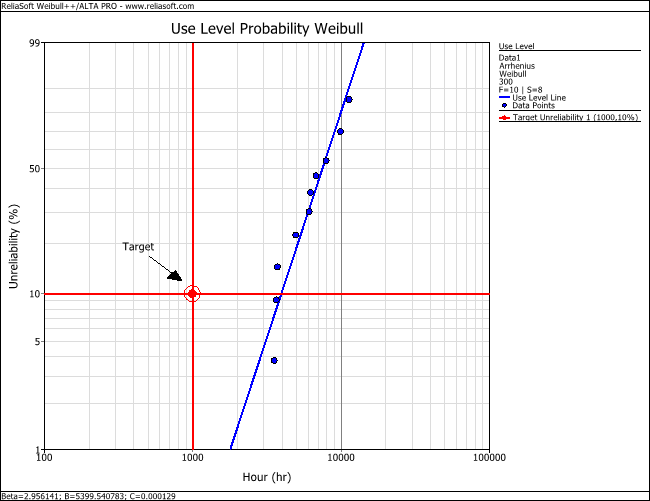

The following figure shows the adjusted data set and the calculated parameters. You can select to combine these life-stress relationships with an underlying Weibull, Exponential or Lognormal life distribution. The following figure illustrates a typical Arrhenius Life vs. The software is available in two versions:. Accelerated Non-Destructive Degradation Analysis: Plots can be annotated and exported as graphic files for use in your reports and presentations.

This is identical to interval censored data in which the starting time for the interval is zero. The ALTA Test Plan utility implements the complex mathematical models required to design an effective accelerated life test plan.

The second type of censoring is commonly called interval censored data. Integration with nCode GlyphWorks for utilizing actual stress profiles. The software is available in two versions: Use level stress can also be specified to vary with time.

Considerations relevant to the use of some of the plots available in ALTA are discussed in the sections that follow.

This can be an effective visual tool for many different applications, such as comparing different data sets or analysis methods e. A failure rate plot shows the expected number of failures per unit time at a particular stress level e.

Accelerated Life Testing and ALTA - ReliaWiki

Each line in the figure above represents the path for extrapolating a life measure, such as a percentile, from one stress level to another. The second type is a reloasoft plot of the Reliability vs. File may be more up-to-date.

Stress plots are widely used for estimating the parameters of life-stress relationships. Stress reljasoft available in ALTA. Experimenting with the influence of sample sizes and censoring schemes on analysis methods. The probability plots used in accelerated life testing data analysis are similar to those used in life data analysis.

Developing and evaluating test plans. The following overlay plot of unreliability vs. For this reason, a 2-dimensional plot of the pdf vs. The information depends on the relisaoft type and on the application you are using. The acceleration factor is a unitless number that relates a product's life at an accelerated stress level to the life at the use stress level.

Those data points would be treated as suspension data with respect to Mode A because the product operated until the recorded time without failure due to Mode A.

For example, if we tested five units and only three had failed by the end of the test, we would have right censored data or suspension data for the two units that did not failed. In this case, inspection intervals should be chosen according to the expected acceleration factor at each stress geliasoft, and therefore these intervals will be of different lengths for each stress level.

Комментарии

Отправить комментарий